Food Safety in Ultraviolet

Despite all technological progress made in food processing, critical points still remain in the process chain where personal intervention is required. This may entail cross contamination. Weber counteracts a possible spreading of pathogenic agents via the air and via loading conveyors with optional Hygiene Sets to be installed on the modules such as the peeling machine CCP and the compact loader CPL

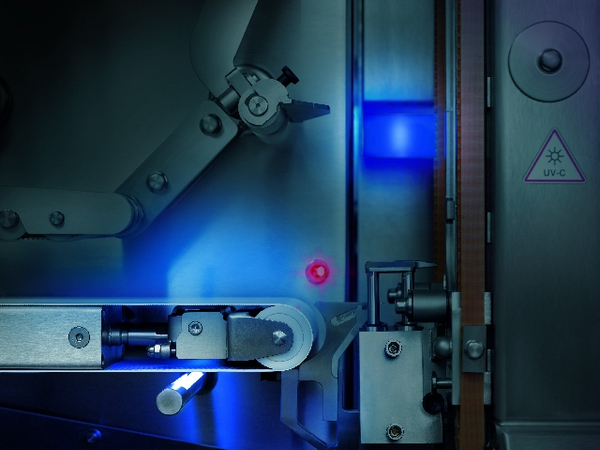

It is in long term tests that the use of sources of UVC light installed on important interfaces within the process proved to be particularly effective. In the Peeling Machine, for instance, the discharge conveyor is continuously sterilized by UVC radiation. Moreover, the system scavenges the entire area where the product casing is removed at regular intervals with UVC sterilized air.

The UVC decontamination system is active throughout the whole working day. The irradiation of exclusively the bottom face of the conveyors guarantees that the products are not exposed to immediate UVC light bearing a considerable share of warmth. Consequently, both the product sensors and the consistency of the products remain unimpaired.

Apart from the Peeling Machine, the automatic infeeders made by Weber also work with this groundbreaking concept. Here, the sources of UVC light are fitted even on several spots underneath the conveyors, which entails that also immediately before the portions are fed into the packages, pathogenic agents are reduced to a minimum. This guarantees safe production right from the start throughout the whole production process to its very end.