The peeling machine fully automatically and hygienically removes the casing of sausage products such as deli meat or salami. This is especially advantageous for large-caliber and long products that are difficult…

Product preparation

Good preparation is key for process automation and efficiency during production. Our peeling machine makes casing removal from sausage and cheese products quick and easy. The weDIVIDE 7000 cheese block divider makes higher yield possible by dividing the raw product into uniform cheese blocks and preparing them for further processing. The Weber wePRESS 5000 forming press perfectly shapes uneven natural products such as raw ham, streaky or back bacon which minimizes product slicing loss and maximizes yield.

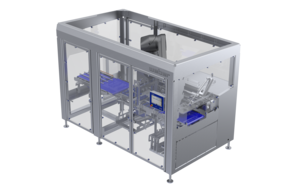

The Weber cheese block divider weDIVIDE 7000 is the perfect start for a high volume and highly automated line. Whether fully integrated or as a stand-alone option, the weDIVIDE divides and prepares cheese blocks…

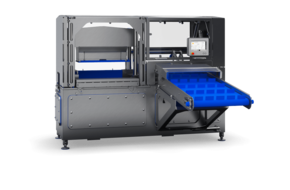

Higher yield, more automation, more sustainability through better product utilization and continuous production: With the Weber forming press wePRESS 5000 products such as streaky bacon, back bacon, cured ham, and…