weSLICE 9500

Unmatched slicing quality and performance: that's the Weber weSLICE 9500 slicer.

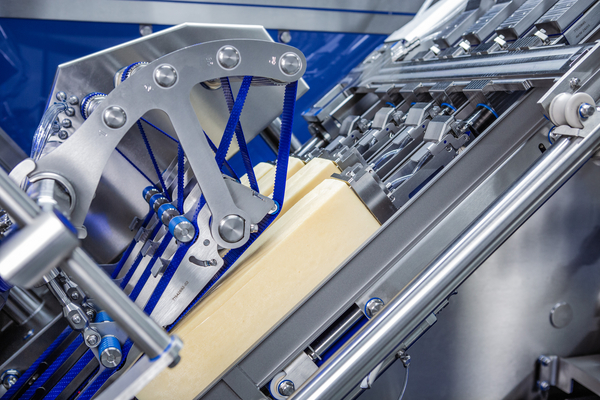

The weSLICE 9500 is Weber's high-performance slicer, setting unparalleled quality and capacity standards. The uncompromising slicing quality and capacity is achieved by using the new Weber DirectDrive technology. Through the direct drive of all feeder components, the product is guided precisely and with care to achieve a perfect and visually appealing slice resultand high portion weight accuracy. Other equipment highlights such as the Weber Durablade Performance involute blade and the Vario technology also contribute to the superior slicing quality. When the Weber vacuum gripper technology is used, the product yield is increased even further, as remaining end pieces are reduced by more than half. The result: a production with almost 100% weight-accurate portions with extremely low give-away. The new Weber Slicer weSLICE 9500 is ergonomically designed with user-friendly safety features such as the new tool-free quick-change system for product holders.

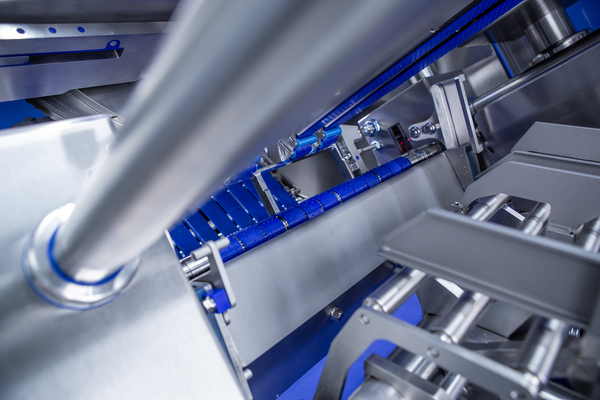

Thanks to the comprehensive line integration, the slicer is able to optimize overall line speed for smoother portion transport and auto-adjust the speed of all downstream components. The line can self-optimize, increasing overall production performance and quality.