feed • scan • weigh

Yield Management

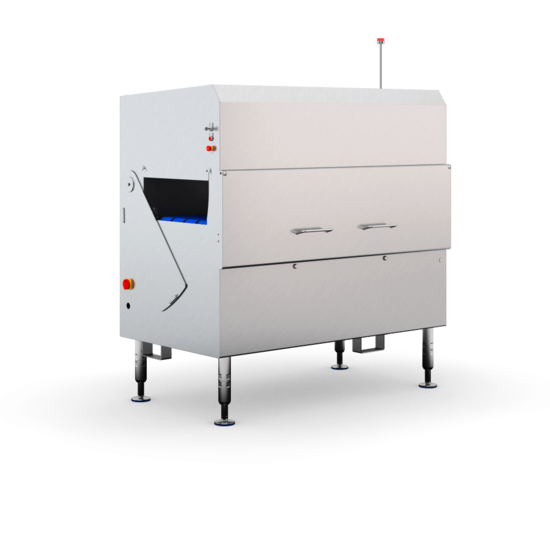

For higher efficiency and yield, we rely on optical systems and precise weighing technology. This ensures the slicer knows exactly what and how to slice. Depending on the product and its specific requirements, we offer laser or X-ray scanning technology for optimal product processing. With our checkweigher, each portion weight is measured and feedback given to the slicer to accurately determine future weight and accurate portion control.

Contact