Slice, transport and package cheese efficiently.

Cheese in all its diversity presents a different, individual challenge at every processing step. With our line solutions, you can master the daily challenges of your cheese production.

Let yourself be inspired by our processing solutions for cheese: from weight-accurate slicing and perfect portioning to the desired presentation in the cheese packaging.

Our solutions

for your success.

To be able to understand your requirements exactly, we listen to you very intensively in the first step. Do you slice hard cheese or soft cheese? Are there other particularities for your unique products? Are there any special technical features that have to be observed in the production process? What are your requirements with regard to portioning, presentation and packaging? Do you want to build up capacities with a new production line or should components be replaced or added to existing slicing lines?

Integration. Flexibility. Efficiency. Along the entire line.

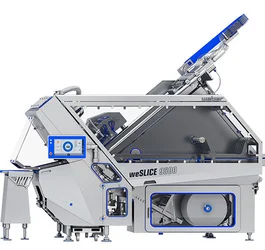

- Tailored to your requirements – our wide portfolio offers solutions for every application in every performance class from trade to industry

- Everything from one source: cheese block divider, LED or X-ray scanner, slicer, infeeder as well as end-of-line equipment

- Smooth production with maximum yield - possible with modules that communicate 100% with each other

- Perfect interaction between cheese, machine and blade thanks to our own Weber blade development and production based on many years of know-how

- Up to 95.5 % yield and thus more profit thanks to vacuum grippers that reduce end pieces by up to 50 %

- Weber is the market leader in output quantity in every slicer class

- More than 99 % good rate (excellent yield or rate of good packs)

- Give-away less than 0.1 %

- Automatic slicing gap monitoring for consistent slice quality

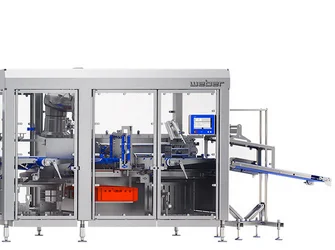

- Change of applications or machine parts "on the fly": if the slicer has run empty, it can already be changed over even though the packaging machine is still running

- Convert to different applications at the push of a button with automation

- Product-carrying parts such as conveyors, grippers, shear bars or tractors can be changed almost without using tools

Solutions for optimization of your cheese production.

Cheese cubes, cheese pieces, and cheese slices on one line.

Our customer asked for the ability to process cubes, pieces, and slices of different types of cheese on one line and thus set a newstandard for flexibility in cheese processing. The changeover between the respective applications should take as little time as possible, of course, in order to maximize the line's operating time.

Flexible Weber line solution for versatile cheese applications.

Raclette cheese, Emmental, Appenzeller, Gruyère, each portioned out and presented differently – no problem at all for a Weber line! Our customer needed a flexible solution for processing versatile cheese applications.

Vepo Cheese on the cooperation with Weber.

We have a long-standing, trusting relationship with many of our customers. Thanks to our experience, technical know-how, innovative developments and excellent service, we offer you real added value and are at your side as a strong partner. We are proud that cheese producers from all over the world trust in our solutions.

Dutch cheese processor Vepo Cheese has relied on production solutions from Weber for over 20 years. There are many reasons for this. Owner Mark Verkleij and technical operations manager Hugo van Put tell us why Weber is the number 1 in the cheese world for them and what else the companies have in common.

Effectively put your cheese in the limelight with Weber.

Your customers' eyes make the purchase. It doesn't matter which layout, presentation, or type of portioning you want for your cheese application: we will put your product in the limelight effectively. Shingled, stacked, overlapped or with interleaver foil? With Weber technology, there are no limits to your ideas.

Sustainable and safe forms of packaging.

In addition to the appealing presentation at the point of sale, the protection and minimum shelf life of your sliced cheese are particularly important success factors. For you, this means more profitability and sustainability and for end consumers, more food safety and taste. Therefore, you should not have to make any compromises when choosing the right packaging for your cheese.

Regardless of whether you decide to use a paper-based foil, PP, mono-PET or APET or if you want a classic MAP packaging, MAP packaging, skin or vacuum packaging: with our thermoforming packaging machine wePACK all packaging materials can be processed. This ensures that your line is also equipped for future requirements.

Flowpacker

Thermoformer

Traysealer

Do you want to package your sliced cheese in trays or tubular bags? No problem! We are also happy to integrate traysealers or flow packers into your Weber line as alternative packaging machines to the thermoformer and take care of seamless integration without interfaces for a smooth production process.

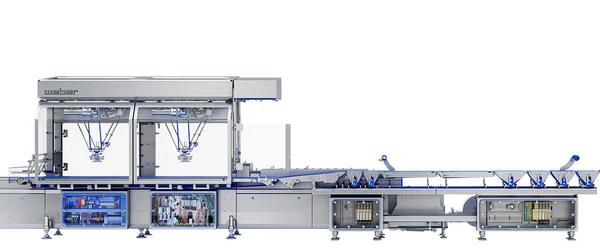

Complete line solutions from a single source.

Being a solution provider, we are passionate about making your catalog of requirements to our project - whether being individual components such as slicers and automation solutions or complex slicing lines. Our broad portfolio offers a wide range of options from product preparation to slicing, buffer, loading and infeed systems to packaging machines and end-of-line equipment. Especially when integrated together, our components unfold their full potential and enrich your cheese production.