Manufacture and package snacks & convenience products efficiently.

The to-go-Market has been booming for years. Whether for lack of time, as a small snack in-between or as an energy booster - the reasons for consumers to reach for a snack are diverse. It is a fact that in many countries around the world, the eating culture is changing and shifting from a few main meals to several small snacks per day. In doing so, the trend “Snackification” relates to ready-to-serve meals for home as well as to-go meals. Retailers and consumers are therefore demanding more and more product variety and have ever higher demands on the appearance, quality and packaging of snacks and convenience products. For you and your production systems, these requirements bring substantial challenges.

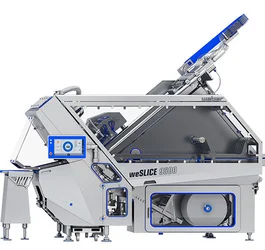

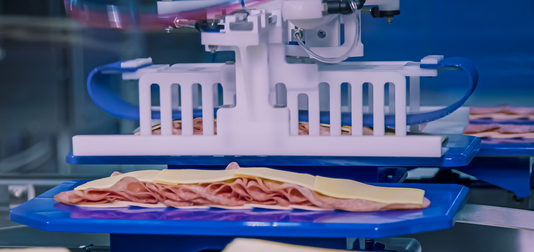

The efficient implementation of different recipes, varieties and variants represent a different, individual challenge at every step of the process. With our hygienic, highly automated slicing, transport and infeeding solutions, you can master the daily challenges of your production. Be inspired by our highly automated production solutions for ready meals, sandwiches, baguettes, pizzas, snack trays and much more.

Our solutions

for your success.

To be able to understand your requirements exactly, we listen to you very intensively in the first step. Which products do you manufacture? How many different recipes and product variants do you want to implement on your production line? Which performance requirements do you have on the technology? What are your requirements with regard to presentation and packaging? Our wide portfolio offers solutions for every application in every performance class from trade to industry.

Automation solutions for snacks & convenience products.

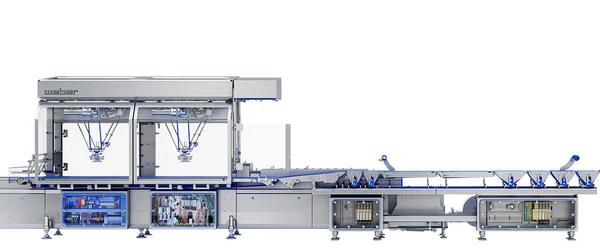

Saving personnel and thus costs, reducing line length and floor space, avoiding manual processes and therefore increasing hygiene and food safety: with the help of comprehensive automation, several challenges within food production can be solved at the same time.

That is why the Weber portfolio offers automation solutions for all these requirements - from the automatic infeeder or the wePICK pick robots to the unique weSHUTTLE system. What you can always expect: scalable solutions with the highest level of automation, central control and seamless networking.

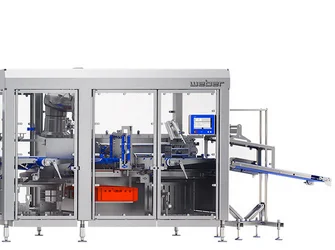

Diverse and safe packaging styles.

In addition to the appealing presentation at the point of sale, the protection and minimum shelf life of your products are particularly important success factors. For you, this means more profitability and sustainability, for end consumers it means more food safety and taste. In doing so, the options for packaging styles are diverse: depending on the product, thermoformed packaging, trays or shrink foil, for example, can be the suitable type of packaging.

Moreover, sustainability and resource-conservation are now relevant factors for consumers that have an influence on purchasing decisions and thus influence the development and design of snacks and convenience products. Reduction of packaging material, recyclability and use of sustainable packaging materials – these and other aspects must therefore be taken into account. Our experts will support and advise you on all topics concerning the design of your packaging as well as on the choice of the appropriate packaging material.

Complete line solutions from a single source.

Being a solution provider we are passionate about making your catalog of requirements to our project - whether being individual components such as slicers and automation solutions for processing and packaging of snacks and convenience products or complex slicing lines. Our broad portfolio offers a wide range of options from product preparation to slicing, buffer, loading and infeed systems to packaging machines and end-of-line equipment. Especially when integrated together, our components unfold their full potential and enrich your production.