Slice, transport & package plant-based products efficiently.

Vegetarian sausage and vegan cheese products have long since ceased to be an emerging trend, but have already arrived in our society and in the refrigerators of the population. Retailers and consumers are therefore continuously demanding more product diversity. However, processing is complex: the consistency and texture of the products made from alternative proteins are demanding and represent a different, individual challenge at every step of the process. With our line solutions, you can master the daily challenges of your production of vegetarian and vegan products.

Let yourself be inspired by our processing solutions for plant-based meat, sausage and cheese alternatives: from hygienic product preparation, weight-accurate slicing and automated infeeding to the desired presentation in the packaging.

Our solutions for your success.

To be able to understand your requirements exactly, we listen to you very intensively in the first step. Is your company already established in the slicing and packaging of food, especially in the production of cold cuts from cheese or meat substitute products? Or are you a newcomer in the sector, either as a start-up or as a reorientation or expansion of your business? What are your requirements with regard to portioning, presentation and packaging?

Solutions for optimization of your production.

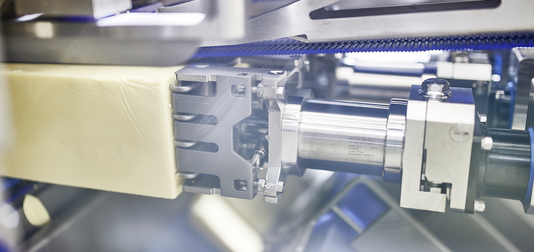

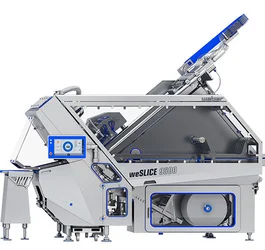

- Uniform slicing from the first to the last slice thanks to precise, lane-dependent guiding of the product to the blade

- Weber Durablade blades exert little pressure to your vegetarian and vegan products – for uniform slicing quality and perfectly placed appetizing-looking slices on each lane

- High precision and product protection due to the interaction of drive technology, blade development and slicing system

- Slicing gap 0: maximum shearing effect, no ripple formation

- Reduce energy and consumption costs: we always develop and manufacture all machines with optimized consumption

- Energy-saving drive technology with controller network and intermediate circuit

- Made in Germany: production exclusively at 6 German locations with 80 % level of in-house production

- Development and use of sustainable technologies such as Weber SprayTech

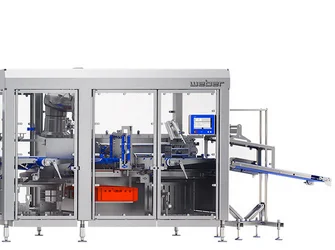

- Weber wePACK thermoforming packaging machine: Machine runability of all foils and sustainable packaging solutions, simplified and shortened infeed processes of new foils

- Tailored to your requirements – our wide portfolio offers solutions for every application in every performance class from trade to industry

- The modular design of our slicing & packaging solutions allows you to grow step by step according to your needs

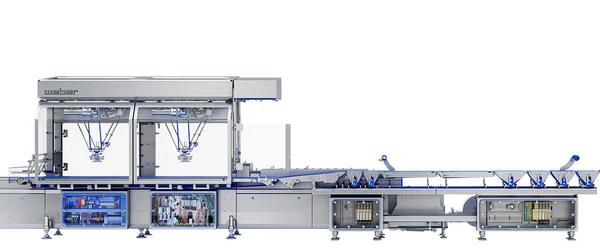

- Everything from one source: LED or X-ray scanner, slicer, infeeder or pick robots, thermoforming packaging machine, buffer and separating systems as well as end-of-line equipment

- Perfect interaction between product, machine and blade thanks to our own blade development and production based on many years of know-how from the market leader for slicers

- Trust in the high availability as well as the special robustness and durability of our machines with a service life of around 25 years

- In case you should need support, our competent, globally available service team is there to assist you personally

- Comprehensive personal services: blade consulting, Weber Academy and Weber Guardian

- Comprehensive digital services: Weber Portal, remote maintenance, AR and VR technology

Highly automated. High-performance. Value-adding.

Throughout the entire line.

Effectively put your vegetarian & vegan products

in the limelight with Weber.

Your customers' eyes make the purchase. It doesn't matter which layout, presentation, or type of portioning you want for your plant-based meat, sausage or substitute cheese products: we will put your product in the limelight effectively. Shingled, folded or stacked? With Weber technology, there are no limits to your ideas.

Sustainable and safe forms of packaging.

In addition to the appealing presentation at the point of sale, the protection and minimum shelf life of your sliced vegetarian and vegan products are particularly important success factors. For you, this means more profitability and sustainability, for end consumers it means more food safety and taste. Therefore, you should not have to make any compromises when choosing the right packaging for your vegetarian sausage and vegan cheese products.

Our experts will advise you on all topics concerning the design of your packaging as well as on the choice of the appropriate packaging material. Regardless of whether you decide to use a paper-based foil, PP, mono-PET or APET or if you want a classic MAP packaging or a multi-layered packing made of soft foil: all packaging materials can be processed with our wePACK thermoforming packaging machine. Naturally different foils can be processed on one machine, to ensure that your line is also equipped for future requirements.

Flowpacker

Thermoformer

Traysealer

Do you want to package your sliced plant-based products in trays or tubular bags? No problem! We are also happy to integrate traysealers or flow packers into your Weber line as alternative packaging machines to the thermoformer and take care of seamless integration without interfaces for a smooth production process.

Complete line solutions from a single source.

Being a solution provider we are passionate about making your catalog of requirements to our project - whether being individual components such as slicers and automation solutions or complex slicing lines. Our broad portfolio offers a wide range of options from product preparation to slicing, buffer, loading and infeed systems to packaging machines and end-of-line equipment. Especially when integrated together, our components unfold their full potential and enrich your production of vegetarian and vegan products.