Fully automatic transport and insertion of portions: The Weber weLOAD 1000 is an automatic infeeder designed for X on X applications and many common die formats with a foil width of max. 460 mm. This optimally…

Scalable solutions from infeeders for standard applications to high-end specialists.

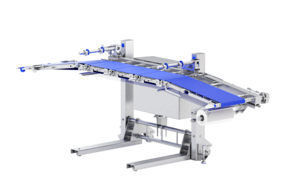

The automatic infeeder weLOAD is an especially compact infeeder that takes the portions created by an upstream unit and places them in a die format suitable for the downstream thermoforming packaging machine. Reloading times of the slicer can be compensated by the integrated buffer area, ensuring a continuous and effective running of the packaging line (depending on the configuration of the buffer area). The automatic feeding of the packaging machine takes place with a transfer that is synchronized with the foil chain.

The scalable weLOAD model range offers solutions from infeeders for standard applications to high-end specialists and can therefore be flexibly adapted to your individual needs. In addition to an extremely compact footprint that allows better accessibility to all areas, the weLOAD infeeders impress with an optimized portion flow and smooth portion transport. The special “GentleTransport” software makes it the perfect solution for sensitive products and applications and generally facilitates full automation without requiring subsequent manual correction or monitoring.

The Weber weLOAD 3000 is an automatic infeeder for transporting sliced portions and other fresh products. The integrated rocker and the possible distribution versions X on X, 1 on X, and 2 on 4 make the weLOAD…

Flexibility in all areas – that is probably the best description of the weLOAD 5000. The automatic infeeder transports portions on up to four lanes and precisely inserts them into the packaging machine. Thanks to…

X on X, 1 on X, 2 on 4, 2 on 3, or 3 on 4 – thanks to the numerous possible distribution versions, the automatic infeeder weLOAD 7000 is the perfect solution for a large number of portion shapes, portion sizes,…

For transporting and inserting sensitive portions such as bacon, the Weber infeeder weLOAD 7500 is the ideal choice. Horizontal product transport, perfected speed sequences across all conveyor units: As a…