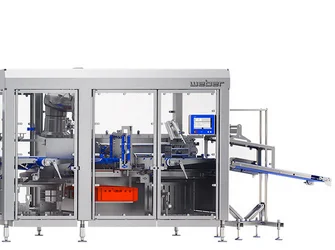

Weber Food Technology.

Your needs drive our innovation.

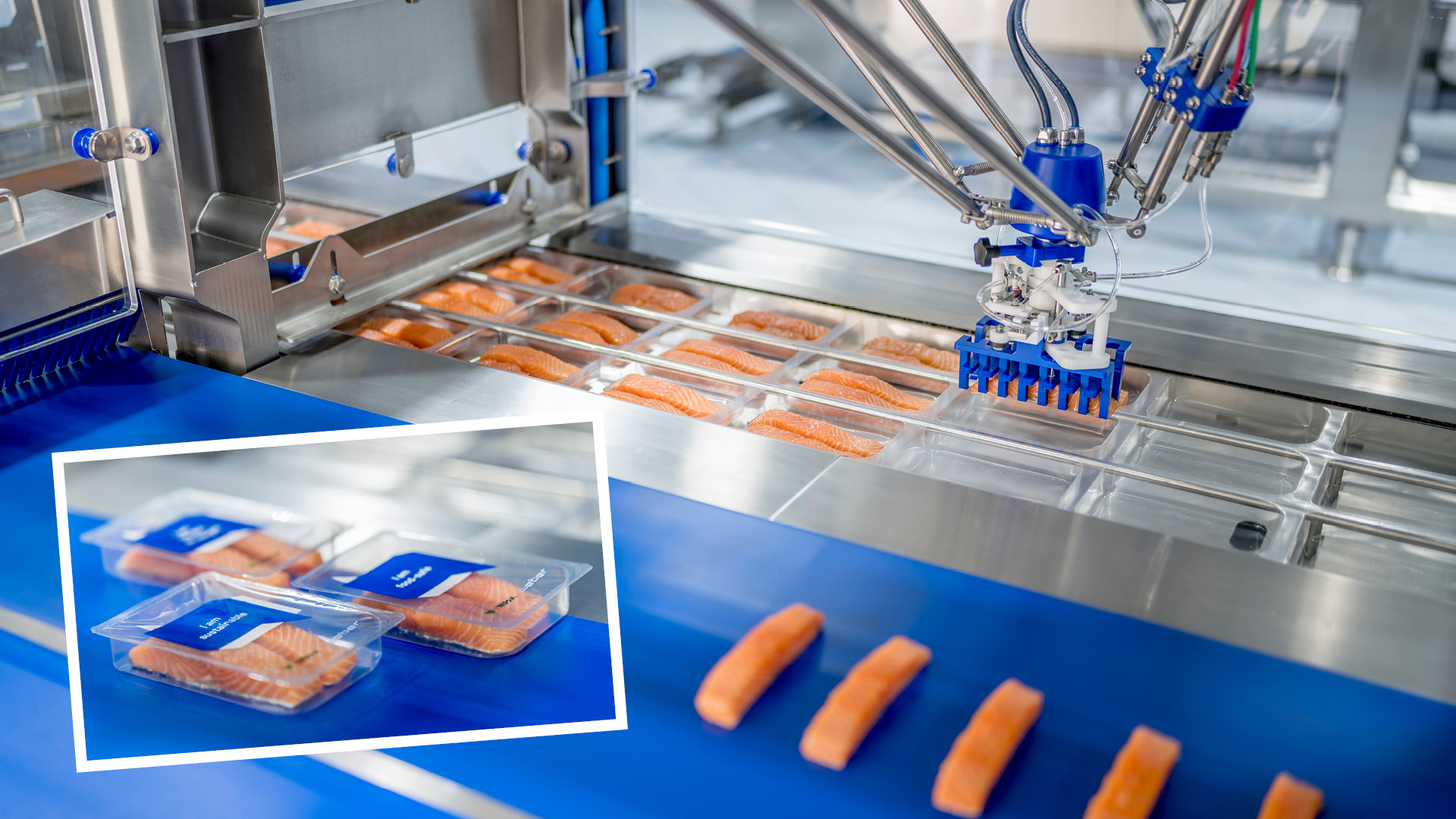

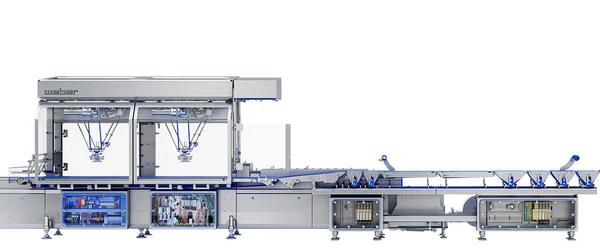

Learn more about our wide range of customized line and automation solutions as well as industry-specific concepts that equip you for emerging market demands. Cheese, sausage & deli, vegan or convenience products. From weight-accurate slicing to precise inserting and packaging. Discover our innovative solutions for the food sector.

From one piece to the sliced product into the packaging.