wePEEL

Product Details

- Removes the casing of sausage products fully automatically and hygienically

- Continuous production: Products are automatically loaded and can be buffered both before and after peeling

- Food safety: The product and the outside of the casing are strictly separated

- Integrated peel tear control to increase process reliability

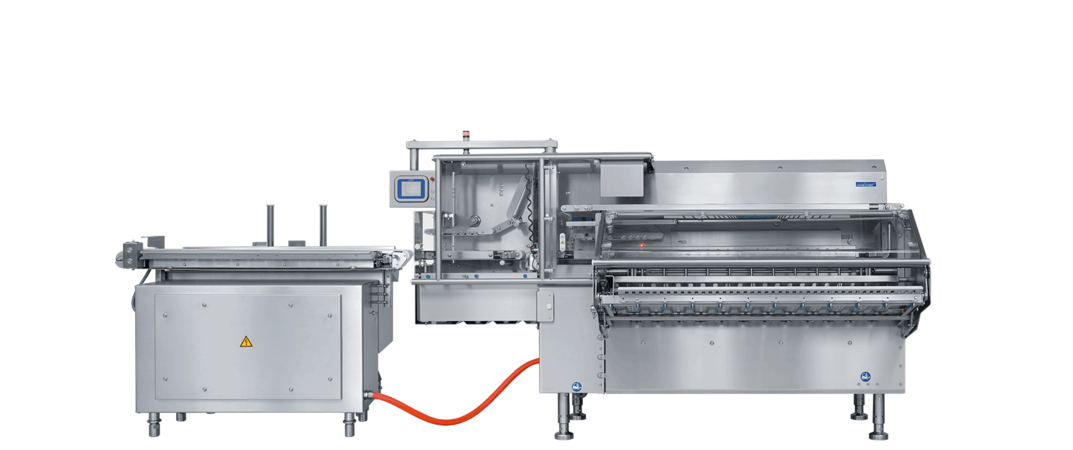

Weber wePEEL: Hygienic and efficient peeling of sausage products.

The peeling machine fully automatically and hygienically removes the casing of sausage products such as deli meat or salami. This is especially advantageous for large-caliber and long products that are difficult to handle manually. In addition, the machine can individually configured. A clear distinction between gray zones and hygiene zones allows the product casing to remain in the gray area, which increases the hygienic safety of the peeled product. With continuous production, the buffer can be inserted both upstream and downstream of peeling.

Technical Data — wePEEL

Max. product width (mm)

165

Height (mm)

2087

Length (mm)

5440

Max. diameter (mm)

165

Max. product height (mm)

50

Min. diameter (mm)

50

Product length (mm)

max. 3200

Width (mm)

3400

Product Videos

Advantages

- Automation of the product preparation to reduce personnel

- Hygiene improvement: Product and outside of the casing are strictly separated; casing remains in the gray area

- Control of peel removal and possible buffering before and after peeling

- Individual configuration possible

- Optional hygiene set:

- UVC irradiation from underneath product conveyors

- UVC air disinfection in the peeling area

Gallery

Contact